Zinc batteries with double efficiency and the ability to produce hydrogen – Innovation Toronto

The Zn-H2 project has the potential to be a breakthrough for a successful energy revolution

Heating homes with solar power in midwinter – the renewable energy revolution wants to build a climate-friendly future for the world. But the move away from fossil fuels will remain a challenge as long as efficient means to store green energy are still lacking. A German research consortium led by Fraunhofer IZM has set itself the ambitious goal to tackle exactly this problem with cheap-to-make zinc batteries that not only store electrical power, but can also be used to produce hydrogen. First tests promise 50% efficiency when storing power and 80% when producing hydrogen – with an estimated life expectancy of ten years. With its fundamental research and practical work on a working demonstrator, the Zn-H2 project has the potential to be a breakthrough for a successful energy revolution.

The renewable energy revolution is creating massive challenges for Germany and other countries around the world. One such challenge: The right means to store green power. Renewable sources like wind and solar are becoming more and more affordable and have the potential to one day supply enough power for long periods of time. But their unpredictable nature means that wind and solar power would always suffer from dunkelflauten, a German term used around the world for those times when the sun does not shine and the wind does not blow. These dunkelflauten currently need to be covered by conventional power plants, forcing countries to maintain a complex dual power infrastructure, burn fossil fuels, and hold back the transition to renewables.

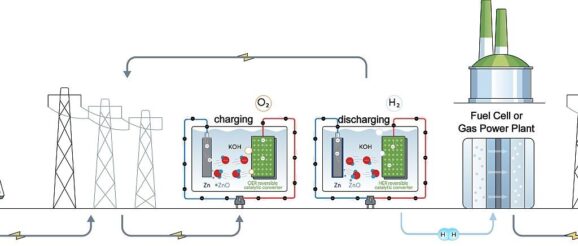

A project consortium of research institutions and the commercial partners Zn2H2 GmbH and Steel PRO Maschinenbau GmbH has teamed up for the Zn-H2 project to investigate innovative ideas for storing green energy. Their vision is to design a long-lasting battery explicitly for the long-term storage of power. Starting with proven battery designs that use zinc anodes, the researchers add alkaline water electrolysis to come up with a completely new technology. By contrast to common lithium batteries, zinc batteries are substantially cheaper and need only easily available, fully recyclable materials (steel, zinc, and potassium hydroxide). And that is not the only trick up their sleeves: The system would be able to produce hydrogen on demand. At the end of their work, the researchers hope to have an electrically rechargeable hydrogen storage system that can store energy in the form of metallic zinc and turn it back into electrical power and hydrogen when needed.

Dr. Robert Hahn of Fraunhofer IZM is in charge of coordinating the work on the project. He explains the chemical processes that happen inside the battery: “During charging, the water oxidizes into oxygen, while reducing the zinc oxide to metallic zinc. This reverts back to zinc oxide during discharge. The water is again reduced and releases hydrogen. This is a unique combination of a regular battery and a source for hydrogen, with a total electrical storage efficiency of 50%, which is double the efficiency of other, currently preferred power-to-gas systems”. As the material cost is an order of magnitude below lithium batteries, the new technology promises a commercially attractive alternative for storing green energy.

The researchers have proven the viability of the new system under laboratory conditions and tested individual cells for their efficiency and stability over a number of cycles. The year end goal is a demonstration unit for operating tests in a dedicated test setup. In the end, eight cells, each with a capacity of around 12 V and 50 Ah, will be connected. For the cost-efficient large-scale production of the dual-function catalyst (producing oxygen and hydrogen in turn), the researchers are putting their trust in galvanic deposition. The process will be tested for its reliability and reproducibility before the actual battery tests.

The Fraunhofer IZM team in Berlin took over the design of the demonstration unit, the construction of the test systems, and the actual reliability tests. Since the zinc-hydrogen batteries are still a world-first, the right test environment had to be developed from the ground up as well, using highly precise and smart controls to adjust and optimize a whole range of parameters.

One crucial parameter concerns charging, which has to be perfectly tuned to guarantee stable operations over several thousands of cycles. This cycle stability has not been achieved in any of the existing state-of-the-art zinc batteries, as the formation of zinc dendrites or mossy zinc typically leads to short circuits at some point in the batteries’ lives.

First tests with individual cells have produced very promising results: In a realistic use cycle with seasonal fluctuations in daylight and in daily use for storing solar power, the cheap-to-build catalysts is expected to provide a service live of ten years or more. The system still needs scaling-up and systems engineering effort before it is ready for industrial use, but one of the commercial partners of the project, Zn2H2, has already several patent applications pending for the technology. Together with the entire research consortium they are thus paving the way for an innovative solution for storing green power and producing hydrogen as one of the fuels powering the renewable energy age.