COVID-19 UPDATE: Innovation a key element of West Virginia’s ongoing COVID-19 response efforts

CHARLESTON,

WV – Since early March, when COVID-19 began to spread across

the United States, West Virginia has been at the forefront of innovative

response efforts.

Using a whole-of-government approach, Gov. Jim Justice has spearheaded a

multi-faceted response, working closely with government agencies, the

business community, West Virginia’s community and technical colleges and

higher education institutions, nonprofit and volunteer organizations, and

citizen groups to build response capabilities throughout the Mountain

State.

Throughout the response to the COVID-19 pandemic, West Virginia has

looked at innovative ways to partner with various organizations to engage

cutting-edge technologies and science to sanitize vehicles and

workspaces, provide additional Personal Protective Equipment (PPE) to

first responders and medical professionals, and to assist with increased

testing capabilities.

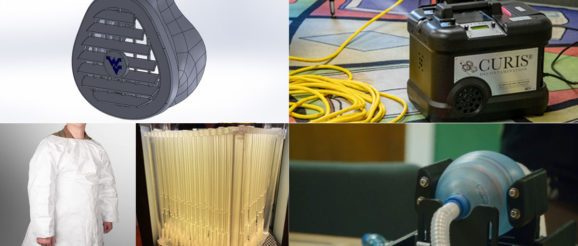

Today, Gov. Justice and other state leaders provided an overview of

several products that have recently been developed in West Virginia to

streamline and broaden response capabilities, including new and

innovative ventilator systems, 3D-printed testing swabs, reusable medical

gowns, protective masks, and Hydrogen Peroxide disinfecting systems.

“I’ve said over and over, I could never be more proud of West Virginia

and West Virginians because they are the heart and soul of this country,”

Gov. Justice said. “At the end of the day, the very thing that they are

the greatest at is that they’re smart. They’re innovative people, they’re

creative people, they’re craftsmen, and you see it right here with what’s

happening.”

As the production of these innovative new products continues, the West

Virginia National Guard (WVNG) will work to build a stockpile of the

items in case a need to further ensure the safety of West Virginians

should arise in the future.

Seeing a national need for ventilators

and not wanting West Virginia to face shortages of the highly

sought-after machines, Azimuth, Inc. of Morgantown teamed with West

Virginia University (WVU) Medical Center and the WVNG to create new

styles of ventilators to aid in patient respiration.

“In conjunction with the West Virginia National Guard and the WVU Medical

Center, Azimuth developed the Automated Bag Ventilator System to increase

our state’s crisis preparedness,” stated Joshua Day a project manager and

electrical engineer for Azimuth, Inc. “Unlike other portable ventilator

systems, our system incorporates patient safety redundancies in a low

cost, low power, and portable solution.”

System design and fabrication were accomplished using Azimuth’s in-house

engineering capabilities while only sourcing a few custom components from

vendors, allowing for quick production and distribution of the new

ventilators to ensure West Virginian citizens were protected and medical

facilities had the critical ventilators on-hand to fight the virus and

save lives.

While testing is a critical element in

helping to fight COVID-19, testing materials such as swabs from both

local supplies and the Strategic National Stockpile were soon depleted

after the pandemic began to sweep the nation. In order to make sure West

Virginians could be properly tested, the WVNG contacted The Innovation

Hub, housed in the WVU Benjamin M. Statler College of Engineering and

Mineral Resources, which partnered with Formlabs, a 3D-printing

technology developer and manufacturer based in Somerville, Massachusetts,

to produce swabs for testing.

WVU and WVU Hospitals are now able to produce up to 10,000 swabs per week

to ensure COVID-19 testing needs are met across the Mountain State.

“One of the most important things identified for our state to combat

COVID-19 is our ability to conduct testing on a large scale,” said

Maj. Gen. James Hoyer, Adjutant General of the WVNG. “Understanding

this vital need, the Guard has stepped up to provide assistance in

procuring the necessary materials to make swabs right here in West

Virginia.

“Just as we have been innovative in developing our own PPE, this is

another example of the type of collaboration and ingenuity that makes

West Virginia stand out from the crowd in our ongoing response to this

pandemic.”

While corporate partner DuPont was busy

delivering stock Tyvek coveralls across the United States to protect

first responders, the company went one step further and developed a new

Tyvek-based material, specifically for COVID-19 response, that is being

produced and retrofitted in West Virginia.

DuPont donated material to West Virginia Correctional Industries which,

in turn, enlisted inmate workers to take the raw material and create

medical gowns in their facilities. Unlike single-use gowns that most

medical facilities utilize, these gowns can be sanitized and reused,

saving facilities expenses and helping to alleviate national supply

shortages of existing gowns.

In addition to the material that was donated by DuPont, Prison Industries

and Mustang Survival have produced more than 3,500 reusable gowns to

date, with more scheduled for production to meet demand in the state.

Perhaps nothing is more emblematic of

the COVID-19 pandemic than face masks. Across the world, face masks,

especially N-95 particulate masks which are used by medical professionals

and first responders, became a desperately needed item soon after the

pandemic began.

The WVNG, working with corporate partners, has developed a new

multi-functional reusable mask, utilizing 3D-printing technology and

innovation that is already being looked at by other states and national

organizations as a potential breakthrough in mask technology.

The mask itself is a soft, form-fitting unit that will mold itself to a

wearer’s face, providing a safe seal, with the benefit of a removable

filtration system. Filter materials can be made from various materials to

meet different requirements, including carbon filters and up to N-95

filtration. Filter materials can be disposed of after use, the mask

sanitized, and with new filter elements can be reutilized hundreds of

times. In addition to the built-in filter flexibility, the mask also

incorporates an oxygen outlet which can allow medical personnel to begin

oxygen treatments for patients without their mask having to be removed,

thereby mitigating potential exposure to harmful pathogens.

The mask, named the West Virginia Mask, is currently being tested by the

National Institute for Occupational Safety and Health (NIOSH) and, upon

approval, will be produced en masse with production goals of 5,000 per

day. The masks will then be provided for free to medical professionals

and first responder agencies throughout West Virginia and will be made

available worldwide for purchase.

Aerosolized Hydrogen Peroxide (AHP)

systems are used in hospitals and medical facilities to disinfect and

sanitize metal and nonmetal medical devices such as surgery tools. The

systems work by utilizing a 7 percent hydrogen peroxide solution that is

vaporized into a dry fog and have been shown to be effective in killing

spores, viruses, mycobacteria, fungi, and bacteria.

Typically, AHP systems are static. However, early in the response

efforts, mobile AHP systems were identified as potentially game-changing

to help disinfect ambulance and first responder vehicles, as well as

building spaces that had been contaminated with COVID-19.

Sgt. 1st Class Brian Tomasek with the WVNG contacted a company based in

Florida that manufactures mobile AHP systems and was able to secure two

such systems to test the validity for mobile use.

Within a week of having the systems in hand, more than 150 ambulances and

first responder vehicles had been tested, and the systems had proven to

be incredibly useful.

Fast forward to the end of May, and the WVNG has procured 22 AHP systems,

which have been used to sanitize numerous daycare facilities, nursing

homes, gyms, workspaces, conference rooms at the West Virginia State

Capitol Complex, thousands of N95 and surgical masks for medical professionals

via a converted mobile cargo container unit, and more than 500 first

responder vehicles. Overall, more than 550 missions utilizing AHP have

been completed around the state, ensuring safe environments and equipment

for personnel and citizens.