A novel solution to drastically reduce world’s largest waste stream and help avoid a sand sustainability crisis – Innovation Toronto

UNIGE and UQ researchers propose novel solution to drastically reduce world’s largest waste stream and help avoid a sand sustainability crisis; by making ore-sand.

After water, sand is the most exploited natural resource on the planet. However, its extraction from seas, rivers, beaches and quarries has an impact on the environment and surrounding communities. A new study by researchers from the University of Geneva (UNIGE) and the University of Queensland’s Sustainable Minerals Institute (SMI) has found that a step-change in mineral processing could drastically reduce mineral waste – the world’s largest waste stream – while creating a sustainable source of sand. Coined “ore-sand”, this material has the potential to address two global sustainability challenges simultaneously, according to the report ‘‘Ore-sand: A potential new solution to the mine tailings and global sand sustainability crises’’.

Concrete, asphalt, glass, electronic chips: sand has many applications. Composed of small mineral particles, this granular material comes from sensitive dynamic environments such as seas, beaches, lakes and rivers or, from static land-based environments such as ancient river deposits and rock quarries. It is estimated that 50 billion tons of sand are used each year. Over the past two decades demand has tripled primarily due to urbanisation and population growth, a trend which is expected to continue with aggregates use reaching beyond 50 Bt per year by 2030.

In addition to the risks of local shortages, the extraction of such a volume of sand has environmental and societal consequences. For example, it is leading to erosion in river banks, which significantly increases the risk of flooding. In some countries, sand mining has caused loss of livelihoods in communities.

Two sustainability challenges with one solution

Researchers from the University of Geneva (UNIGE) and from the Sustainable Minerals Institute at the University of Queensland (UQ), Australia, have researched the potential of a viable alternative to naturally occurring sand. This material, presented in a recent report published by the two universities, has been coined ‘‘ore-sand’’.

UNIGE’s Adjunct Professor at Department F.-A. Forel for environmental and aquatic sciences of the Faculty of Science, Pascal Peduzzi said that “ore-sand has the largest potential in volume for reducing the amount of sand taken in the natural environment. By using what has been so far considered as ‘‘left over’’ material, the project gives an important impetus towards a more circular economy.”

The production of ore-sand can help reduce the production of mineral mining waste and thus the further build-up of mine tailings. Mineral wastes from the mining of ores currently represents the largest waste stream on the planet, estimated between 30-60 billion tonnes per year. These residues come from crushing operations to extract certain metals from the rock.

SMI’s Development Minerals Program Leader Professor Daniel Franks said ore-sand has the potential to address two global sustainability challenges simultaneously. “Separating and repurposing these sand-like materials before they are added to the waste stream would not only significantly reduce the volume of waste being generated but could also create a responsible source of sand.”

Reduction of carbon emissions

The 12-month study independently sampled and investigated sand produced from iron ore mining, pioneered by Vale S.A in Brazil, which has previously experienced tailings dam failures. After an analysis of the chemical properties and some refining operations, the researchers were able to demonstrate that part of the material stream which would otherwise end up as mining residues could be used as a substitute for construction and industrial sand, in the same way as recycled concrete and steel slag. “If these results can be replicated with other types of mineral ores there is potential for major reductions in global mine tailings.”

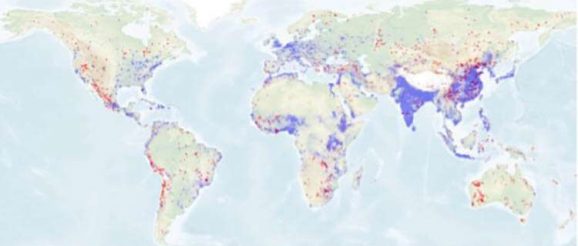

“By mapping mining locations worldwide and modelling global sand consumption, we discovered that almost a third of mine sites can find at least some demand for ore-sand within a 50 km range. This could contribute to at least 10% reduction in the volume of tailings generation at each site. Simultaneously, almost half of the global sand market (by volume) could find a local source of ore-sand. For example, ore-sand could potentially substitute 1 billion metric tons of sand demand in China”, explains Daniel Franks.

In addition, the life cycle assessment of ore-sand, based on the Vale case, shows that substituting naturally sourced sand with ore-sand could potentially lead to net reductions in carbon emissions during sand production. The carbon emissions by transport is however a key consideration.

A benefit for mining companies

“Considering the co-production of ore-sand is a significant advantage for mining companies: it reduces the large tailings which hinder operational mining activities, while at the same time can generate additional revenues. Ore-sand is a step towards a “no tailings mine’’, explains Pascal Peduzzi. Developing countries have fewer options for using recycled aggregate materials, given their more recent infrastructure. However, many have mining operations that can generate ore-sand as a by-product.”

Some of the next steps are to collaborate with aggregate market players to demonstrate this substitute material’s ease-of-use, performance and sourcing process. Findings from the study were presented at the 5th United Nations Environment Assembly. A new UNEA resolution (UNEP/EA5/L18/REV.1) on ‘‘Environmental aspects of minerals and metals management’’ calls for strengthened scientific, technical and policy knowledge with regard to sand to support global policies and action regarding its environmentally sound extraction and use.