ENGINEERING INNOVATION WITH THE MIDLANDS’ CHANGEMAKERS

A trip to AV Birch in deepest Shropshire is a joy, and a glimpse into what the future holds for the timber and fencing sectors.

This is no pie in the sky sci-fi story but a tale of engineering innovators tackling real-world issues in a bid to boost productivity and improve safety.

The business was founded in 1977 as a small engineering firm focused on building presses for the construction truss industry. That soon morphed into the provision of engineering solutions for a wider range of industries and sectors to the point where, today, they stand out as a beacon of innovation. Midland’s ingenuity at its finest!

A chat with Director Graham Clark and Dave Bradley, Sales Engineer for automated machine sales, reflects the genuine enthusiasm that AV Birch has for responding to bespoke industry requirements with machinery that ticks all the boxes.

Graham explained: “We see the industry as constantly moving forward, constantly adapting to new challenges and AV Birch is there to ensure that process is as smooth as possible. Existing machinery is often old and antiquated and unable to respond to ever-changing needs. We aim to create machines and technological processes that are as future proof as possible.”

Case in point is A V Birch’s ever-growing range of machinery focused at UK sawmills. Just ask Norfolk-based Thomson Sawmills who have recently collaborated closely with David and his team to exponentially boost their productive capacity. By all accounts, Thomson are just the first of many sawmills to get on the A V Birch automation bus with interest expressed by timber firms of all sizes.

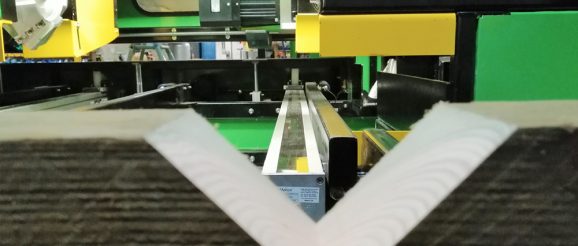

Dave commented: “Thomson wanted us to build a machine that pre-notched fence posts. We visited a number of sawmills to assess where existing manual operations could be automated. The result was a machine that can process a 54 pack of fence posts in 8 and a half minutes as opposed to the two hours plus it would take using the traditional cross-cut saw way.

“We’ve now built on that to add extra functionality and flexibility for auto feeding and auto stacking. We never stand still. We are constantly looking to refine and improve with a view to making the production process as smooth and effective as possible in a way that fits in with our customers’ budgets whatever the size of the sawmill in question.

“Using those same ground rules, we’ve gone on to engineer a tenoning machine and morticing technologies that are already having an impact in the real world,” added Dave.

Laura Grimwood, joint MD of Thomson Sawmills, took up the story: “The team at AV Birchworked with us to put together ideas about new machines we were looking to invest in to help speed up production and service our customers’ needs.

“They came up with ideas that we hadn’t thought of. We’ve already manufactured two machines with them and I’m sure a third and fourth will follow soon!” added Laura.

Thomson Sawmills Production Manager Tom Smith echoed those words: “If you don’t move forwards you get left behind. With A V Birch’s tenoning machine we’ve gone from 1200 units per day to 4000. They’ve helped us increase production, deliver enhanced reliability for our customers and improve the safety of our staff.”

A V Birch was tasked by BSW to produce an incising machine. Sure enough, they duly delivered and demand is now booming for their incising technologies representing an effective way of increasing the lifespan of ground contact posts.

Dave added: “We come across a lot of machinery from the US and elsewhere that we are able to improve on. Change is a constant with A V Birch. For instance, we are gradually gravitating away from hydraulic to electrical motors. That offers even more gains when it comes to productivity and safety as well as providing us with real-time data that boosts the capacity for preventative maintenance such as telling the operators when replacement saws and other components are needed.

“We field enquiries from sawmills of all sizes that are seeking to get a competitive advantage. We give them the tools to achieve that with productivity gains and returns on investment that are always impressive.

“A V Birch have calculated their machines can pay for themselves in as little as 6 months.”

Change is good and nowhere is that clearer than in the workshops of A V Birch who really are forging ahead for the good of the timber and fencing sectors. Changemakers indeed!

01746 714418 [email protected]

The post ENGINEERING INNOVATION WITH THE MIDLANDS’ CHANGEMAKERS appeared first on Fencing and Landscaping News.