BAUMA: Liebherr hydrogen excavator leads Innovation Award winners

The historic Munich Residence in the centre of the city was the opulent setting for the announcement of the thirteenth Bauma Innovation Award winners – with Liebherr France SAS leading the pack and scooping the first award of the evening for its hydrogen-powered excavator, the R 9XX H2.

iVT was there as it was recognised in the hotly contested Climate Protection category in the Bauma Innovation Awards. The hydrogen-combustion machine, the first ever Liebherr hydraulic excavator to be powered by a hydrogen engine, is being displayed on the OEM’s outdoor stand (pictured above) at the Messe München exhibition this week (24-30 October).

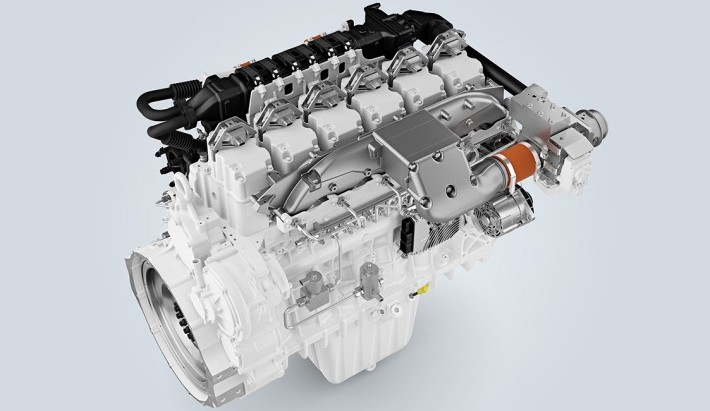

Liebherr H966 hydrogen combustion engine

The machine’s prime mover is the H966 hydrogen combustion engine, and yet it is said to match an equivalent diesel machine in power, dynamics and responsiveness, so that an operator will notice no difference. The engine has six cylinders and uses port fuel injection (PFI), which Liebherr employs along with direct injection (DI) for its hydrogen engines. Liebherr’s components product segment plans to start with the series production of hydrogen motors by 2025.

The audience at Max Joseph Hall waits expectantly for the announcement of the Buama Innovation Award winners

The other four lucky winners who received their accolades last night (Sunday 23 October) in the Max Joseph Hall at the Munich Residence were:

• MiC 4.0, which won in the Digitalisation category for its Machines in Construction, which creates one common digital language for construction sites;

• Herrenknecht AG, which earned the prize in the Mechanical Engineering category for its continuous advance tunnelling machine, which can speed operations by 1.6x.

• Holcim (Germany) GmbH, which narrowly led the field in the Construction category with its new, hugely versatile, patent-pending building material, CPC (Carbon Pre-stressed Concrete)

• And finally for Research, Freiberg University of Mining and Technology Mechanical Engineering Institute won with their Deep Sea Sampling technology – a way to facilitate the mining of sea-bed minerals and resources, with minimal environmental impact.

The award winners

Further details of winners and all the nominees are available on the Bauma Innovation Awards website.

A total of 133 entries were received, of which 41 finalists made it to the next round. In two rounds of voting, the expert jury and task force chose their favourites. The trade journalists attending the Bauma Media Dialog in Munich also had the opportunity to cast their vote in the final round.

The competition is a joint project under the auspices of the VDMA Construction – Equipment and Plant Engineering, Messe München, the Federation of the German Construction Industry (HDB), the German Construction Confederation (ZDB) and the German Building Materials Association (bbs).

The post BAUMA: Liebherr hydrogen excavator leads Innovation Award winners appeared first on Industrial Vehicle Technology International.