Cemented Carbide 3D Printing Process Earns CERATIZIT Group Innovation Award – 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing

We’ve seen all sorts of 3D printed components made out of metals and metal alloys over the last several years, including tungsten, steel, stainless steel, nickel, cobalt chromium, copper, iron, aluminum, and even precious metals like gold. However, with the exception of VBN Components and its patented hard metal Vibenite 480 material, it’s been difficult to find a reliable AM process for fabricating cemented carbide parts that are consistent in quality and performance. But, this week the CERATIZIT Group, a Luxembourg-headquartered specialist in hard materials, announced that it is the recipient of an Innovation Award from the multi-sector FEDIL business federation for its 3D printed cemented carbide parts.

The global carbide technology pioneer has been around for more than 95 years, and constantly invests in research and development in order to develop the best new carbide, ceramic, and cermet grades in hard materials, which it uses to produce specialized cutting tools, wear parts, indexable inserts, and rods. CERATIZIT holds more than 1,000 patents for its hard material solutions, which are being used in a variety of industries, including aerospace, automotive, and toolmaking, mechanical engineering and medical, and oil and gas.

Director of Research Dr. Ralph Useldinger and Project Manager Dr. Christian Lamberti at the 2020 Innovation Award ceremony

CERATIZIT won this year’s 2020 Innovation Award from FEDIL in the ‘Process’ category for its new 3D printing process of tungsten carbide-cobalt, which the company refers to in a press release as an “ideal solution for small volumes and high component complexity.”

“Additive manufacturing of carbide products provides us with more flexibility in terms of implementing customer requirements and opens new design possibilities, which we can use to offer our customers highly optimised, individual solutions in minimum time,” stated CERATIZIT’s Head of R&D Dr. Ralph Useldinger in the release.

Dr. Useldinger further explained that the company’s customers will also benefit from the active support in optimizing product design that CERATIZIT offers.

So, why exactly is it so important to find a good 3D printing process for cemented carbide parts? Carbide is a powder-metallurgical material with a hard material phase and a metal binder one, which gives it the appropriate amount of hardness and toughness for industrial use. In terms of cemented carbides used in wear protection and cutting tool applications, tungsten carbide often acts as the hard carbide phase and cobalt is the metal binder, so that, according to CERATIZIT, “the best physical and mechanical properties can be obtained.”

Tools made with this hard material can withstand higher temperatures than usual, which makes it a good choice for industrial tooling applications, and even 3D printer nozzles. Cemented carbide also has electrical and thermal conductivity, superior wear resistance, and good compressive and impact strength. 3D printing cemented carbide components can help save on time and costs during prototyping or small batch production, as well as during the design phase. Additionally, the technology allows users to create far more complex shapes with free-form contours than conventional manufacturing processes could offer, such as undercuts and interior channels, and can also decrease the number of components and assemblies needed.

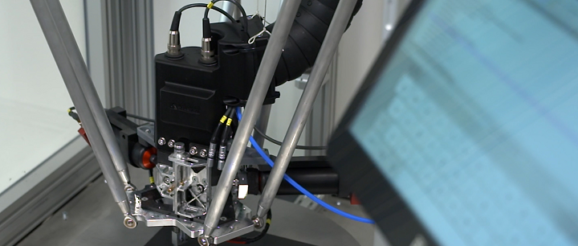

Additive manufacturing of carbide components

“With its newly developed process, CERATIZIT not only achieves the customary quality of products manufactured by pressing and machining but can also respond better to customer requirements,” the release states.

(Source/Images: CERATIZIT)