How Vertical Farming Is Impacting The Food Supply Chain And Enabling Taste Innovation – CB Insights Research

With media attention and funding at all-time highs, we break down how vertical farms operate, who is investing, and how it affects grocery retailers.

Where is this data coming from?

The Covid-19 pandemic exposed vulnerabilities in traditional farming methods and food supply chains. Eleven major grocery retailers in the US saw an average 38% out-of-stock rate during the start of the pandemic, according to Statista.

As a result, investors are paying more attention to startups that have found ways to shorten the produce supply chain while employing more sustainable practices, increasing food security, and innovating with tastes and textures.

The STATE OF RETAIL Q1’21: Investment & Sector Trends To Watch

Funding to retail tech is off to its fastest run rate in 5 years. Download our free report to get all the trends.

Vertical farming allows food to be grown in hyper-controlled environments that are closer to urban areas, free of pests, and produce more frequent harvests. These innovations will benefit grocery retailers by providing diversified produce sourcing as well as new assortments.

News mentions of “vertical farming” have more than tripled since May 2020. The topic has also been garnering executive attention from companies like retail tech firm Ocado Group, with earnings transcripts mentions hitting an all-time high in Q1’21.

Vertical farming is positioned to have a profound impact on customer preferences and the food industry at large. Below, we address the following questions:

What is vertical farming?

The chart below summarizes what retailers and food brands need to know about how vertical farming compares to traditional methods:

Please click to enlarge.

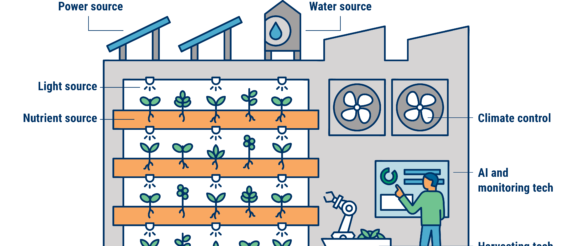

There are multiple methods of vertical farming, but ultimately the main components are:

Many modern vertical farms also employ AI technology that uses sensors and cameras to monitor plant health and adjust environments accordingly.

PHYSICAL STRUCTURE

Vertical farming structures differ from traditional greenhouses in that they take up less land per square foot of growing space and can be retrofitted into existing buildings. This allows vertical farms to have a higher yield per square meter — about 1 square meter of vertical farm can produce as much as 50 square meters from a traditional farm.

This means farms can be set up close to urban areas without the need for new construction. For instance, AeroFarms has repurposed a steel mill, nightclub, and laser tag facility in Newark, New Jersey.

Using abandoned industrial buildings is a way for vertical farms to compete with more traditional large-scale operations, but there are also options for smaller, more modular forms. For example, South Korea-based n.thing repurposes shipping containers into vertical farms. Because of their structure, the shipping containers can be stacked and combined to create a variety of configurations to fit different spaces.

Want the full post? Become a CB Insights customer.

If you’re already a customer, log in here.