Innovation and Value Addition- Lifeline of Future Textile and Apparel Industry of Bangladesh

Maeen Md. Khairul Akter,

Managing Editor, Textile Focus

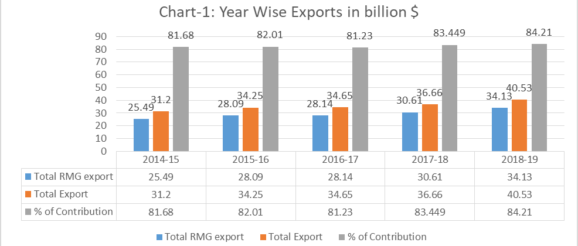

Bangladesh is a major country in the global textile and apparel supply chain as one of the major supplier of readymade garments to the world market. In terms of readymade knitwear and woven wear exports Bangladesh resides just after China with around 6% market share. In Bangladesh textile and apparel industry is the lifeline of economy as apparel exports constitutes more than 80% of the total exports from the country with 13% contribution in the total GDP. In the last 40 years the apparel industry of Bangladesh has grown tremendously. In 2018-19 total exports from the apparel industry stood at 34.13 billion dollars with a commendable 11.49% growth. Of the $34.13 billion, Knitwear products fetched $16.88 billion, which is 11.19% higher than last fiscal year. Woven items earned $17.24 billion, registering an 11.79% growth.

However, from the beginning of the current fiscal year 2019-20 exports showed negative growth month on month for 4 straight months which indicates an alarming situation ahead. Though exports got back to positive streak in December, 19 with a mere 2.89% growth, the overall trend still indicates a tough time ahead for the industry. Adding to the miseries, more than 200 garments factories have been shut down in the first six months in this fiscal year reporting continual losses in their business.

So, if the overall scenario is analyzed, as the chart-2 depicts, garments orders are in the lower side may be due to the down turn of the global economy off late. Rise of BDT value against USD is also indicated by many stake holders as a reason for making low or no profit. If these are the reasons hopefully, the situation will improve as the global economy recovers and if the government is offering any policy support for the time being. But in longer run, the situation is becoming more and more out of control if measures and necessary changes are not embraced as soon as possible.

Insightful analysis of chart-1 shows that every year the contribution of garments export in the total export basket of the country is increasing. It means, the economy is getting more and more dependent on a single industry and other sectors are not being developed aside. In economics such scenario is termed as ‘Dutch effect’, long term consequence of which is devastating. Another issue the export figures does not clearly reveal is the net earnings. The export figures are actually total revenue, not the profit. A major portion of the currency earned is spent to import raw materials specially, yarn, fabric, dyes and chemicals. So at the end of the day the money manufacturers are getting in hand is not significant. As a result, it becomes difficult for them to invest in expansion or developing their business to the next level. It’s a vicious cycle in which most of the small and medium industries are being succumbed due to their low capacity and capability. This is the main reason for which many small garments factories are being shut down in recent times as they are simply any more unable to make enough profit to continue business. And not to forget about the rise of costs in doing business in the recent times with hikes in utility, transportation and raw material prices. Matter of great regret is that, the price garments buyers are paying has not increased meanwhile, rather declined on average by 3-4% on FOB in last decade. So local manufacturers are being squeezed from both sides leaving them in complete despair.

So, if the overall scenario is analyzed, one major problem comes into surface that the industries are not making enough profit to continue business. The scenario can be explained with the simplest equation of profit that is profit equals revenue minus costs. In the last decade the costs of doing business has surged by at least 30 to 40%, as a result the margin for profit has become so narrow that only the factories with better operation practices are able to survive. If the industries are not making enough profit there will be no investment, no expansion, very little scope for business development and wealth creation. This is what happening to the factories that were reluctant over the years to embrace the positive changes and now they are being unable to survive anymore.

In this circumstances, innovation and value addition in the industries can be the lifeline of the textile and apparel industry in the upcoming future. Again from the equation we can see that for making profit industries need to increase their revenue or reduce costs. Revenue can be increased by increasing sales volume, which is the strategy adopted by most of the apparel manufacturers in Bangladesh. To increase sales, factories have to grab more orders and increase their productivity. Most of the factories in Bangladesh operates at 45 to 55% efficiency which is below par. Now days, many of the industries are working to improve their productivity and adopting innovative solutions like industrial engineering, lean manufacturing etc. Still we are not good enough in productivity compared to our competitors. So there is still a huge scope to improve productivity, It’s a continuous process and the industries must look for innovative solutions in this regard. As far as the revenue is concerned the preferred way to sustainable increase it by adding value. To add value, our manufacturers have to claim better price for their products. This is not being possible as we do not have indigenous design capability and technology. In most of the cases we only copy paste the buyer’s designs leaving very less scope to claim better prices. Industries must develop capabilities for new product development, quality improvement and more value added options so that there are scopes to churn out the additional profit needed from business. Another strategy for asking premium prices is by going green by investing in eco-friendly solutions and producing eco-friendly products as there is a huge demand of it in the consumer market. So, if the factories are not working to develop the mentioned capabilities it will be impossible for them to survive in the near future.

If working on increasing revenues seems overwhelming for the factories, another way of enhancing profitability is by reducing and optimizing the costs. For this innovation in resource and process optimization is required. Resource optimization can be ensured with little or no investment only by improving the processes or by ensuring better planning and coordination. Many factories who are toiling hard to make profit and is not in a position to invest in revenue generating innovations must adopt cost minimizing solutions at least so that their costs do not surpass their revenues. Process optimization innovations are already evident in the garments industries in the form of industrial engineering. They are trying to optimize the production processes to ensure the highest possible productivity in the industries. But still there are lots scope of adopting more effective processes and technologies like the lean manufacturing.

In a nutshell, industries must have to find out ways of making profit. There is no other way but to embrace the above mentioned value added and innovative activities for that. In short term, as most of the apparel manufacturing business have less or no control on product price, they must look for other innovative solutions to control their costs by optimizing their production processes and improve their productivity as much as possible. But in long term, industries must gradually invest and develop more indigenous capabilities like product development, quality improvement, technology improvement, designing and development so that we can emerge as our own ‘Made in Bangladesh’ brand and claim prices according to our interests. As we already have the basic industries here it is quite feasible develop more value added industries in the near future if the appropriate steps are taken by the stake holders. Our entrepreneurs are believed to have the passion and resiliency to cope up such transformations, so we can hope for transformed textile and apparel industry in the near future.

The post Innovation and Value Addition- Lifeline of Future Textile and Apparel Industry of Bangladesh appeared first on Textile News, Views & Articles.