Innovation in Organic Solar Cells Promise Low-Cost, Bendable, and Efficient Panels

Korean researchers have created electrodes designed for use in all-organic solar cells using inexpensive zinc oxide, promising a dramatic upgrade in photovoltaic energy.

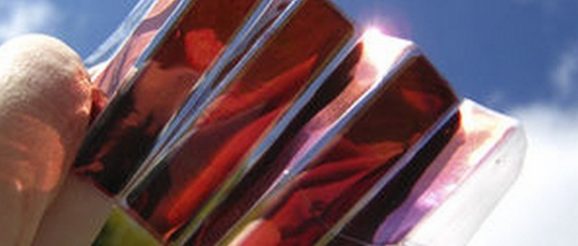

Organic solar cells (OSCs) are foreseen to be light weight, flexible, and of a high conversion efficiency. But, most OSC electrodes use indium tin oxide, which is too costly and fragile to enable the manufacture of flexible, large-area solar panels with OSCs.

If the indium tin oxide could be replaced, the cells could be not only be made more cheaply, but in many national cases, domestically. Even in an advanced country like South Korea, the production of indium tin oxide was so impracticable, that all such material was imported from abroad.

Organic solar cells have desirable features and massive commercial potential. Their light weight, flexibility, malleability, and, most importantly the high power-conversion-efficiency of any kind of light, whether natural or unnatural, direct or indirect, make them ideal for a wide range of applications.

Now, Dr. Hongkyu Kang and Prof. Kwanghee Lee from the Gwangju Institute of Science and Technology recently put forth a new method to create OSCs using inexpensive zinc oxide, the active ingredient in non-chemical sunscreen, that overcame the issues of cost and scalability without comprising the high power-conversion-efficiency inherent in organic solar cells.

Most OSCs are produced using a technique called “spin coating”, which allows for high power conversion, but makes for poor scalability.

The team mapped a zinc oxide nanoparticle layer using a “blade coating” technique, which is a little like putting a screen protector on a phone; whereby a small about of liquid is deposited continuously through a small opening before a blade-like tool smooths it over the material in question.

Creating a uniform bilayer on an ultrathin silver-film electrode, the OSC maintained its flexibility and high energy conversion from sunlight.

“The ultrathin silver film electrode with [zinc] bilayer has the flexibility, wettability, and high surface energy of ITO but is not brittle or expensive,” said Dr. Kang. “This makes it easier to use ZnO for manufacturing organic solar cells and developing a printing technology for large-area solar cell technology.”

OSCs manufactured in this way demonstrated an efficiency of 7.67% for a module area of 0.5 square feet, which makes it the most efficient large-area OSC when compared to previous research.

Another advantage is that zinc is a byproduct of many separate mining operations for things like gold, silver, and copper, so existing established supply chains are available for future OSC producers.

Kang and Lee’s research was part of an industry-university collaboration, and they transferred it to MSWAY Co., Ltd., a South Korea-based electronics company which had been entirely dependent on foreign imports as the domestic production of indium tin oxide didn’t really exist.

With the new technology, the pair expect that a value chain will be established for the commercialization of OSCs with construction and equipment companies.

“Our method opens doors to the commercial use of these OSCs, such as their integration into building walls and windows to realize self-sustaining buildings,” said Prof. Lee.

SHARE This Remarkable Innovation On Social Media…