Maker’s Mark Head of Innovation Jane Bowie Explains the 2 Year Process that led to RC6 Bourbon Whisky | Distillery Trail

It was the first day of fall and Head of Innovation Jane Bowie arrived to work at Maker’s Mark Distillery in Loretto, Kentucky. With her car windows rolled down she parked her car near Regauge an area where the smell of freshly dumped barrels of fully matured Maker’s Mark bourbon filled the air. It was a reminder that although the world knows and loves the caramel and vanilla aromas coming from bourbon it is a much more complex spirit. As someone who experiences the entire bourbon making process from yeast jug to fermentation to barrel dumping Jane knows there are many other beautiful scents that fill her day. One of her favorites starts inside their yeast jug. It’s the same yeast strain they’ve been using from day one and the inspiration for their latest release.

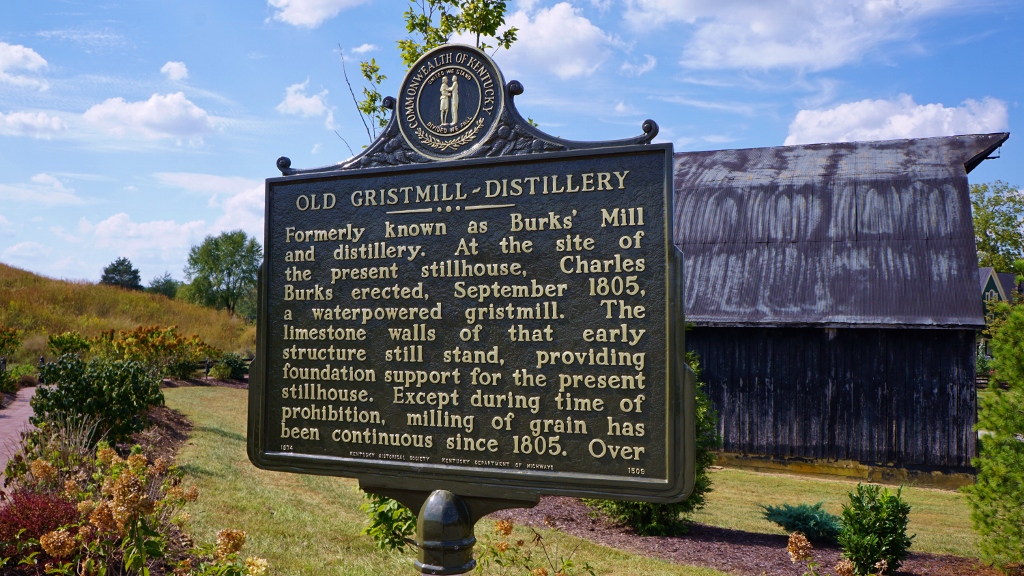

- Burks’ Gristmill and Distillery Built 1805.

- Maker’s Mark Distillery built c~1889.

Historical records show that distillation started on this site with Charles Burk in 1805. In 1889 his family built many of the buildings that make up the core of what is the distillery today. Distillation stopped and started several times at this location until the Post-Prohibition era when T. William Samuels purchased the property on October 1, 1953. Mashing, distilling and barreling began in 1954 and given that the Samuel’s family was making bourbon the world never saw a drop of their new spirit until they were bottling four years later in 1958. And as they say the rest of the story for this high wheated bourbon is history.

Like many distillers, the folks at Maker’s Mark are a superstitious bunch. They are not known for change. When it came time to expand operations to keep up with demand they simply mirrored the distillation equipment they already had. When it came time to expand again they did the same thing, a mirror image of what they had. When you visit the distillery and walk into the distillation room you will literally think you are looking into a mirror. For the most part, the bourbon from this Loretto distillery hasn’t varied much since its 1950s founding. That changed in 2010 when Bill Samuel’s, Jr. decided he wanted to leave his own mark on the brand by making a new bourbon something that he defines as ‘Yummy.’ The result of that search for yummy was the release of Maker’s 46. After working with their partner Independent Stave Company on 122 wood finishing experiments they landed on experiment No. 46. It’s a fully matured Maker’s that was aged for an additional 9 weeks with 10 seared French oak staves placed inside the barrel. When it came to naming the new bourbon they kept it simple and went with Maker’s 46.

- Maker’s Mark Distillery’s Head of Innovation Jane Bowie.

Another Maker’s Mark innovation that came to fruition with the Independent Stave partnership was Maker’s Private Select series in 2016. Private Select allows customers to purchase a single barrel of fully matured cask strength Maker’s that has been aged an additional 9 weeks with a variety of 10 oak staves. Customers spend nearly a full day at the distillery tasting various combinations of bourbon finished with five different types of staves until they decide on their own personal taste profile. The math tells us there’s a total possible combination of 1,001 taste profiles that could be generated based on any combination of staves a customer chooses.

The Inspiration Behind Maker’s Mark Limited Edition RC6

- Cypress fermentation tanks from 1889.

- Maker’s Mark Jug Yeast that inspired RC6.

The newest release of Maker’s Mark Wood Finishing Series is RC6. We recently had the pleasure of spending ‘A Day on the Trail’ with Maker’s Mark Head of Innovation Jane Bowie at the distillery to learn more about this new limited release.

Our first question with Jane was the new RC6 simply a variation of their previous 122 experiments? The short answer is no, RC6 is a brand new expression.

“When I drive in to Maker’s Mark Distillery in the morning on the first day of fall and its cool enough to have my windows rolled down I often park near Regauge,” said Bowie. “When I drive in near Regauge when they are dumping barrels it always used to smell like apples to me. Denny Potter (Maker’s Mark Master Distiller) and I talk a lot about this, Maker’s has such a fruit forward flavor from the yeast but it never gets top billing because everything in bourbon is about vanilla and caramel. Those things get top billing. And those things are wonderful but bourbon is so complex and the whole thing with this wood finishing series is that we want to highlight different flavor aspects created by different processes. So, the yeast was the inspiration for this RC6.”

“This is the Maker’s Mark family yeast. Maker’s has two full-time employees that their only job is to make yeast. Many modern day distillers have dropped the use of yeast jugs and have moved to dry yeast. At Maker’s Mark we still propagate from the jug. The yeast is made from the mother strain everyday.”

“We are making jug yeast from the mother strain every six weeks. To me, this (yeast) is what’s going to be the biggest flavor driver before the barrel gets involved. This is what dictates what’s created during fermentation. It kind of drinks like a hefeweizen. It’s got all of those banana and orange and apple and fruit characteristics but there’s like a clove and spice note too. This will be a huge flavor driver. This is really the inspiration behind RC6.”

With that in mind, the goal of the new release was to pull out that flavor in the finished product. For help to do that Jane turned to Independent Stave Company.

- Andrew Wiehebrink Director of Spirit Research & Innovation at Independent Stave Company.

- Independent Stave Company Research Center.

- Independent Stave Company’s Kentucky Cooperage.

“This project was very different from what we usually do with oak finishing,” said Andrew Wiehebrink, Director Of Spirit Research & Innovation at Independent Stave Company. “Under normal circumstances, we add staves because we want to ADD specific wood derived flavors that are not already in the liquid, and we are pretty good at that. With this project, it wasn’t so much about adding new flavors; the flavors we wanted were already there. We had to figure out a way to design an oak product that promoted flavors not associated with oak. After two years of tasting, reworking, and more tasting…RC6”

The 2 Year Journey to RC6 Started with a Taste Vision

“We start with a taste vision,” explained Bowie. “They do the wood science. We taste together. We give him notes. Some staves get eliminated. Some we go ok, if you could change this and this, we think it gets closer. They go away, tweak the wood, we go again.”

“This is the original bottle of this project. There were 12 samples. I tasted in the lab and I tasted at home. Tasting in a lab is not the same thing as tasting at home. You need both. The first soaks we did was September 17, 2017. From there we would make notes and we would go back to Independent Stave and say can you tweak this, can you try this. And we do iteration after iteration tweaking it.”

“We don’t make barrels of everything. We do what’s called bottle soaks. What happens with these bottle soaks is you have a proportion of wood. Here’s the thing. It gives you a general idea but it is nowhere near the complexity or intensity of a barrel. But it gives you an idea. We’ve tasted over 500 species of wood in the last five years. Once we feel good, we make barrels of it. For this project we’ve identified we need a minimum of three barrels to statistically verify something.”

Stay Informed: Sign up here for the Distillery Trail free email newsletter and be the first to get all the latest news, trends, job listings and events in your inbox.

Where Did the Name RC6 Come From?

We know the story of Maker’s 46. We asked Jane if RC6 was similar and it was the sixth test of something? We were close.

“This was the very first project they worked on in the Independent Stave Research Center that opened two years ago. This was the very first project to come out of part of the lab. When we got it, it was labeled KY RC 1, KY RC 2, KY RC 3 – Kentucky Research Center Stave 1, Stave 2. Stave 6, KY RC6 was the stave we latched onto from the first project and then we kept tweaking it. We dropped the KY and stuck with RC6.”

“The staves amplify notes of ripe fruit balanced with layers of baking spice – a taste profile inspired by Maker’s proprietary yeast strain.”

Maker’s Mark Wood Finishing Series 2019 Limited Release Stave Profile RC6 is available now at the distillery and at retailers nationally. There were only 255 barrels produced and once it’s gone, it’s gone. It’s bottled at cask strength of 108.2 proof (54.1% ABV) and has a suggested retail price of $59.99 for a 750mL bottle.

And finally, if you have not been to the Maker’s Mark Distillery you need to add this to your bucket list. The history, artwork, food and spirits tasting is an experience you will treasure.

Learn more about Maker’s Mark Distillery.

View all Kentucky Distilleries.

Maker’s Mark Wood Finishing Series 2019 RC6

Please help to support Distillery Trail. Sign up for our Newsletter, like us on Facebook and follow us on Twitter.

Please help to support Distillery Trail. Sign up for our Newsletter, like us on Facebook and follow us on Twitter.