Reducing the expensive and environmentally damaging effects of overfertilising soil with low-cost AI soil sensors – Innovation Toronto

The technology, which is described today in Nature Food, could help growers work out the best time to use fertiliser on their crops and how much is needed, taking into account factors such as the weather and the condition of the soil. This would reduce the expensive and environmentally damaging effects of overfertilising soil, which releases the greenhouse gas nitrous oxide and can pollute soil and waterways.

Overfertilisation has so far rendered 12 per cent of once-arable land worldwide unusable and the use of nitrogen-based fertiliser has risen by 600 per cent in the last 50 years. However, it is difficult for crop growers to precisely tailor their own fertiliser use: too much and they risk environmental damage and money wastage; too little and they risk poor crop yields. The researchers behind this new sensing technology say it could provide benefits for both the environment and growers.

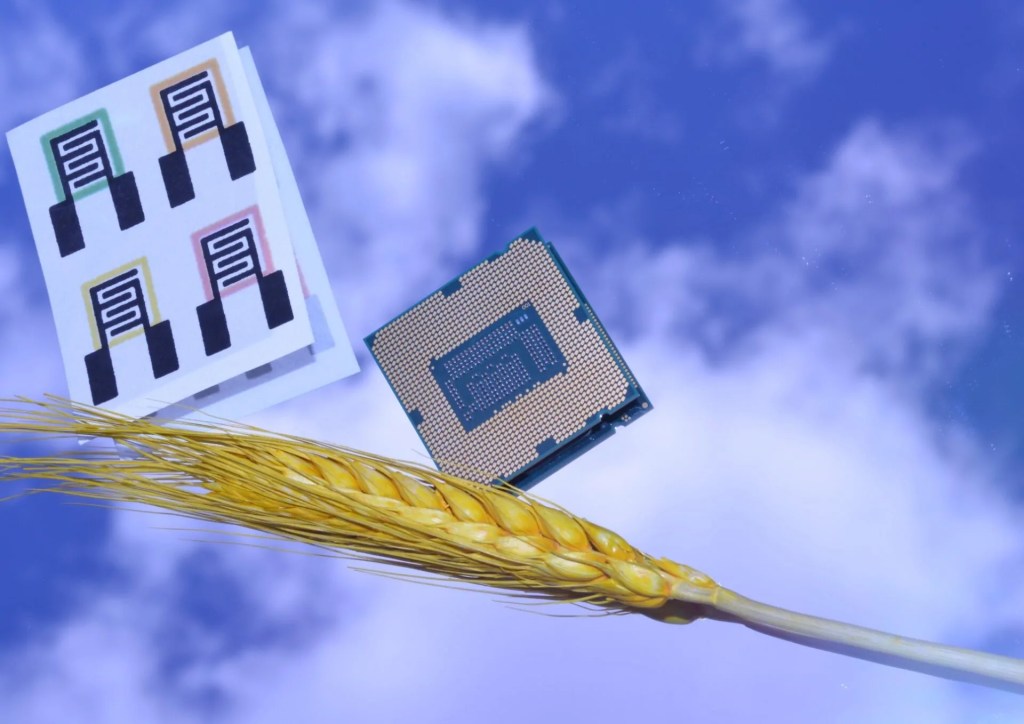

The sensor, named chemically functionalised paper-based electrical gas sensor (chemPEGS), measures levels of ammonium in soil – the compound that is converted to nitrites and nitrates by soil bacteria. Using a type of artificial intelligence called machine learning, it combines this with weather data, time since fertilisation, pH, and soil conductivity measurements. It uses these data to predict how much total nitrogen the soil has now and how much it will have up to 12 days in the future, to predict the optimum time for fertilisation.

The research study identifies how this new low-cost solution could help growers yield maximum crops with minimal fertilisation, particularly for fertiliser-thirsty crops like wheat. The technology could simultaneously reduce growers’ expenses and environmental harm from nitrogen-based fertilisers – the most widely used fertiliser type.

Lead researcher Dr Max Grell, who co-developed the technology at Imperial College London’s Department of Bioengineering, said: “It’s difficult to overstate the problem of overfertilisation both environmentally and economically. Yields and resulting income are down year by year, and growers don’t currently have the tools they need to combat this.

“Our technology could help to tackle this problem by empowering growers to know how much ammonia and nitrate are currently in soil, and to predict how much there will be in the future based on weather conditions. This could let them fine-tune fertilisation to the specific needs of the soil and crops.”

Nitrogen pollution

Excess nitrogen fertiliser releases nitrous oxide into the air, a greenhouse gas 300 times more potent than carbon dioxide and which contributes to the climate crisis. Excess fertiliser can also be washed by rain into waterways where it deprives aquatic life of oxygen, leading to algal blooms and reduced biodiversity.

However it remains difficult to precisely tailor levels of fertilisation to soil and crop needs. Testing is rare and current ways to measure soil nitrogen involve sending soil samples to laboratories – a lengthy and expensive process whose results are of limited use by the time they reach the grower.

This new low-cost approach could expedite the process of testing the soil. While chemPEGS only measures ammonium, the machine learning component allows it to predict current levels of nitrate and future levels of nitrate and ammonium in the soil.

Senior author and principal investigator Dr Firat Guder, from Imperial’s Department of Bioengineering, said: “Much of our food comes from soil – a non-renewable resource which we’ll lose if we don’t look after it. This, combined with nitrogen pollution from agriculture, presents a conundrum for the planet – one that we hope to help tackle with precision agriculture.

“Our sensing technology can measure and predict soil nitrogen with enough accuracy to forecast the impact of weather on fertilisation planning, and tune timing for crop requirements, which we hope will help to reduce overfertilisation while improving crop yields and profits for growers.”

The researchers expect chemPEGS and associated AI technology, which are currently in prototype stage, to be available for commercialisation in three to five years with more testing and manufacturing standardisation.