Space – the next frontier – requires innovation in nuclear fuel design and testing – INL

To go where no man has gone before (and to get back) will require quite a bit of oomph. All that energy must come from somewhere. Traditional chemical rocket fuels could work for some missions, but nuclear-based propulsion systems have several advantages.

Nuclear thermal propulsion (NTP) rockets use a nuclear reaction to heat liquid hydrogen. When the hydrogen is heated, it expands and is forced through a nozzle to produce thrust. This is similar to how air can stream out of the stem of a balloon and cause it to fly across the room. With rockets, this happens with much greater speed and force.

These hydrogen propelled rockets are designed for space exploration, not for use on Earth, and subsequently would not be turned on (i.e. brought critical) until after they left Earth. Although the specific type of fuel for these applications has not been formally selected, the fuel envisioned for use in an NTP environment is uranium fuel.

Scientists believe that these rockets will be at least twice as efficient as chemical fuel-based rockets, require a fraction of the space on launches from Earth, provide an extra margin for error correction, and could significantly reduce the time required to fly to Mars. This last point is crucial, as it will reduce the amount of time that a human crew is exposed to cancer-causing cosmic radiation.

This summer, INL researchers used the Transient Reactor Test Facility (TREAT) to determine if new candidate fuels can endure the extreme heat and pressure that would exist in a nuclear thermal rocket.

“TREAT offers unique capabilities to test fuels and structural components under extreme and harsh environmental conditions,” said Rob O’Brien, INL’s director of Advanced Manufacturing and principal investigator for nuclear thermal propulsion fuels research and development.

On June 19, researchers performed the first reactor-based test of a new candidate fuel. The 1,200 degrees Fahrenheit practice run was used to validate computer models, to test a new sensor and an experiment capsule developed for the project, and to identify the reactor settings to be used in an ongoing series of tests at extreme temperatures. In upcoming TREAT tests, the fuel will reach close to 3,000 Kelvin in less than 30 seconds—that’s nearly 5,000 F!

For several years, NASA has been collaborating with national laboratories including Idaho National Laboratory, Los Alamos National Laboratory and Oak Ridge National Laboratory to develop new nuclear fuels that will make these rockets a reality. The goal is to identify the best materials, composite structures, and optimum uranium compounds needed for production of fuels that are robust, reliable, and cost-effective for the harshest of environments.

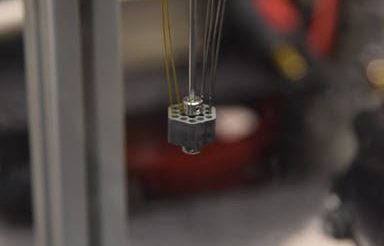

In order to make a super high-density fuel source able to withstand the temperature and pressure required for nuclear propulsion, INL scientists used an advanced manufacturing technique called spark plasma sintering to rapidly fuse mixtures of metal and ceramic powders to build the fuel composite used in the TREAT test. Development of these composites will allow the fuel to survive the harsh temperatures that will be needed for nuclear thermal rockets.

The design characteristics of the new fuel composites also increases safety. Their structure encapsulates the uranium at the microscopic level, keeping the byproducts of the fission reaction safely contained inside millions of tiny enclosed reaction capsules within the solid composites. Thus, the fission reaction’s heat can pass through the composite to power the rocket, but the radioactive byproducts cannot escape.

“The DOE national laboratories are looking forward to working with NASA to further develop fuels for nuclear thermal propulsion systems so that these systems can provide more efficient space travel in the years ahead,” said Douglas Burns, the INL-DOE program manager for NASA’s nuclear thermal propulsion program.

Learn more about TREAT: https://factsheets.inl.gov/FactSheets/Transient_Reactor_Test_Facility.pdf

Learn about TREAT’s recent restart: https://inl.gov/article/inls-treat-reactor-successfully-completes-first-fueled-experiment/

Take a virtual tour of TREAT and check out other INL 360 virtual tours: https://inl.gov/360-tour-map/

Posted Oct. 22, 2019