The Making of the Iconic Plastic Pink Lawn Flamingo | Lemelson Center for the Study of Invention and Innovation

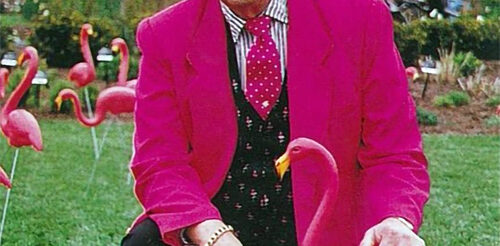

Dynamic duo: the original flamingos designed by Donald Featherstone. Courtesy of Union Products Division of Cado Co., Fitchburg, Massachusetts

Soon after the COVID-19 pandemic lockdown started, one friendly neighbor began posting a series of scavenger hunts on our neighborhood listserv to provide stress relief and an excuse to get some fresh air. The theme of the first hunt was “one-of-a-kind” house and garden decorations. Scanning the list, I was not surprised that there were not one but three plastic pink lawn flamingos, widely considered the prime example of kitsch Americana décor, in my immediate vicinity. In searching for their whereabouts, I became curious about who had created them and how they were made, so I decided to look into it.

In 1956, Don Featherstone, a recent art school graduate, became an industrial designer. He worked for Union Products of Leominster, Massachusetts, which manufactured plastic lawn and garden decorations. The town was a hotspot of plastic production, with sixty companies making everything from Foster Grant eyeglass frames to Tupperware. Union Products merchandise appealed to first-time homeowners of post-World War II working-class subdivisions who were looking to add pizazz to their property.

Featherstone’s second assignment for Union Products (out of almost 650) was to design an ornamental flamingo. Americans had long associated the flamingo with South America and the Caribbean, the bird’s native habitat. The exotic bird was also culturally connected to South Florida—a fashionable vacation destination for the wealthy for decades—where flamingos had once lived in great numbers. Union Products hoped the faux coral-colored bird would offer customers a little cachet as well as tap into other trends of the day, including interest in Caribbean culture and love of all things pink.

Although flamingos in Florida had been hunted into near oblivion by the twentieth century, places like Miami’s grand Flamingo Hotel helped solidify the exotic bird’s place in high society. Souvenir card of a mural in the Flamingo Hotel, Miami Beach, Florida, 1921. Courtesy of artandcolour

Lacking a live model for his flamingo, Featherstone drew inspiration from a photo spread featuring the birds that appeared in the October 1957 issue of National Geographic. Soon, he had sculpted in clay a pair of Phoenicopterus Ruber Plasticus—as he later jokingly referred to them. One stood upright and alert, the other stooped as if feeding. A steel mold was created for each sculpted bird, and they were mass-produced in polyethylene.

The inspiration for Donald Featherstone’s ornamental flamingos was Carleton Mitchell and B. Anthony Stewart’s article, “Ballerinas in Pink,” in National Geographic Magazine, October 1957.

The original process used to manufacture the plastic flamingos, known as injection mold technology, dates to the nineteenth century. John Wesley Hyatt and his brother Isaiah received a patent in 1872 for an apparatus to improve the manufacture of products made from the early plastic called celluloid. A plunger, functioning like a large hypodermic needle, compressed heated celluloid and then injected it into a mold. In this way, the Hyatts made it possible to cheaply produce all sorts of products in quantity. Initially, goods traditionally made of expensive materials that were in high demand and short supply—ivory, tortoise shell, and gemstones—were targeted for manufacture.

While the Hyatts’ process made using plastic more feasible, it was not flawless and could result in imperfections. In 1946, James Watson Hendry resolved these issues by inventing a machine that relied on a rotating screw rather than a plunging mechanism. The rotating screw enabled manufacturers to mix and heat the plastic more uniformly and better control the injection speed. These changes, as well as advancements in materials, greatly improved the quality of plastics products made using injection mold technology.

A newly molded pair of Featherstone flamingos. Courtesy of Andrea Shea/WBUR

When Featherstone’s flamingos were initially made, the two halves of each bird were injection molded, then glued together. However, in the early 1970s, Union Products began to manufacture the birds with blow molding technology. Initially invented in 1938 by Enoch Ferngren and William Kopitke and inspired by glass blowing, this method used compressed air to blow molten plastic into a mold. First used to make bottles, plastics manufacturers eventually realized that the technology could be used to create containers and other hollow products of all sizes and shapes.

Extreme NIMBYism? The ubiquitous plastic pink flamingo. Artwork by Malcom and Linda Geiger Denemark, “There Goes the Neighborhood.” From Don Featherstone and Tom Herzing, The Original Pink Flamingos: Splendor on the Grass. Schiffer Publishing, 1999. Courtesy of Alexxa Gotthardt/Artsy

Today, injection molding and blow molding remain among the top technologies used in plastics manufacturing, from children’s toys to car interiors to medical equipment. Regarding Featherstone’s plastic pink flamingo, the court of public opinion remains split. Some consider the avian decorations tasteful; others find them tacky. However, with over 20 million pairs sold as of 2018 and sales of the birds (as well as knockoffs) still going strong, they have and for the foreseeable future will continue to delight or dismay the neighbors.