VCU’s Virginia Microelectronics Center joins new statewide network for semiconductor innovation – VCU News – Virginia Commonwealth University

At the C. Kenneth and Dianne Harris Wright Virginia Microelectronics Center, starting small is the key to making a big impact. Located in Virginia Commonwealth University’s College of Engineering, the VMC is dedicated to developing novel materials and electronic devices on the micro- and nanoscale to tackle some of the biggest technological issues facing society today.

Now, the center is helping strengthen the future of the semiconductor industry in the state by joining VAST – the Virginia Alliance for Semiconductor Technology.

Announced in April by Gov. Glenn Youngkin, VAST is a collaboration among academic institutions, government agencies and industry partners to expand access to resources and promote training programs for semiconductor research and fabrication. The $3.3 million initiative is funded by GO Virginia, a bipartisan, business-led economic development program.

The VAST initiative, led by Virginia Tech, will also involve the University of Virginia, George Mason University, Norfolk State University and Northern Virginia Community College. A memorandum of understanding among the institutions was signed during the CHIPS for Virginia Summit in July.

“This is an incredible opportunity for our academic institutions to come together to serve as a catalyst for faculty, students and entrepreneurs to advance in this field. It’s a great example of what we can accomplish when science is done as a collective,” said P. Srirama Rao, Ph.D., vice president for research and innovation at VCU. “The VMC is one of the oldest clean room facilities for semiconductor and microelectronics development in Virginia. Our strong research and education programs, as well as our connections with government and industry partners, put us in a position to be a robust collaborator in addressing the needs of the commonwealth and the country. I feel very inspired when I see what is possible.”

“Our research facilities and faculty at the College of Engineering are deeply committed to microelectronics research and building up the semiconductor workforce. I’m incredibly excited by the potential of what Virginia’s academic community can deliver as a result of this collaboration,” said Azim Eskandarian, D.Sc., dean and William H. Goodwin Jr. Endowed Chair of the VCU College of Engineering. “Through the VAST initiative, we are not only advancing semiconductor technology but also creating meaningful changes to our community and country, as well as providing more opportunities for our undergraduate students to be a part of the transformative innovation ecosystem we have cultivated.”

A renewed vision for American prominence

Semiconductor chips are made from thin slices of material – such as silicon, gallium arsenide or gallium nitride – and designed with intricate patterns of switching devices that manage the flow of data and computation. These chips serve as the brains of modern electronics, controlling how devices process, store and receive information. They are the building blocks for technology used in our daily lives, such as smartphones, cars, LED lights and home appliances, but they also are powerful enough to be used for supercomputers, hypersonic aircraft, medical diagnostic tools and other complex scientific endeavors.

The United States has historically been a powerhouse in the semiconductor industry, but today, only 12% of the global supply of chips are produced domestically. Approximately 75% of the world’s modern chip manufacturing is now handled in East Asia, primarily in Taiwan and South Korea. This disparity in production was felt most heavily during the initial recovery period from the pandemic, when the global output of semiconductor chips failed to keep up with increasing demands.

To reinvigorate U.S. research and manufacturing, the federal government passed the CHIPS and Science Act of 2022. The legislation is a $52 billion investment that seeks to incentivize domestic semiconductor production, create higher-paying manufacturing jobs and improve U.S. technological competitiveness on the global stage.

VAST will build on the CHIPS Act momentum by initiating research partnerships and workforce development across Virginia to bolster the national semiconductor ecosystem.

“We are now in a situation where we often rely on other countries to supply the semiconductor chips that are so critical for our technological innovations. From a national security standpoint, there is renewed interest in building our semiconductor infrastructure with the goal of becoming more self-reliant in manufacturing microelectronics,” Rao said.

The power of collective effort

Through the VAST initiative, collaborating institutions will establish partnerships to engage the entire breadth of facilities, labs and equipment dedicated to nanotechnology and fabrication of semiconductors and microelectronic devices. As part of this mission, the VMC is establishing a fee-based facility usage model, which will allow researchers, students and industrial partners within Virginia to utilize the VCU center’s capabilities as they study and develop new devices.

“The vision of the alliance is to establish a network of universities within the commonwealth of Virginia that will operate in a synergistic way to advance semiconductor research,” said Nibir Dhar, Ph.D., director of the VMC and a professor in the Department of Electrical and Computer Engineering at the College of Engineering. “The VAST program will serve as a central node to connect students and researchers with tools or training opportunities at partner institutions to further their studies. Individually, each university is operating their own facilities, but collectively, we will have much more capabilities for the research community.”

Established more than 20 years ago, the VMC was the first of its kind in Virginia to support research and development in the field of semiconductor chips. The center’s mission and capabilities have since expanded to provide the tools and technical support needed to address the scientific challenges of the 21st century.

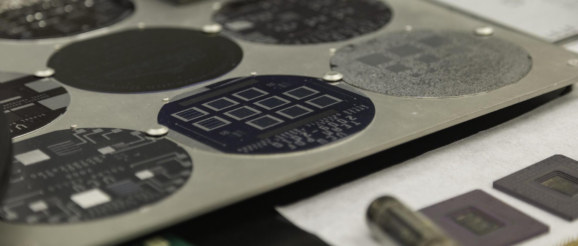

The $11 million facility includes more than 8,000 square feet of clean room space that offers a nearly particle-free environment for faculty, staff, students and industry partners to work on new technologies.

“When we process microchips or microelectronics, the last thing we want is some foreign particle or particulates to accumulate on the surface, as that would kill the devices we are trying to create,” Dhar said.

The center also offers a suite of state-of-the-art tools that allow researchers to build semiconductor materials atom by atom, then use those materials to fabricate new micro- and nanodevices. Researchers who utilize the facility are developing innovations relevant to various fields and industries, such as bioelectronics for medical therapies, infrared cameras for remote monitoring, electrical systems for smart cities, and wireless radio frequency and infrared optical communication technologies for the next generation of mobile networks and free space communication.

“We have more than 20 tools that cover every stage of semiconductor and microelectronics development. This includes equipment for carving patterns in semiconductor wafers, tools for depositing metals and other compounds to create highly precise structures, as well as auxiliary technology to collect data on new materials and devices,” said Vitaliy Avrutin, Ph.D., associate director of the VMC and associate professor in the Department of Electrical and Computer Engineering. “We’re continuously looking for ways to add more capabilities to cover the needs of the research community within VCU and now across Virginia.”

The VMC is also strategically located near complementary centers, such as the Nanomaterials Core Characterization Facility, a research site shared by VCU’s College of Engineering and College of Humanities and Sciences. At the NCC, researchers can analyze the characteristics of the materials they have produced.

“This allows us to study the properties, qualities and performance of a material created at the VMC before we begin with fabricating devices,” Dhar said. “Between these two facilities, we have an incredibly strong foundation for building microelectronics from the ground up.”

Developing the semiconductor workforce

In addition to creating a network for research, VAST is training the next generation of scientists, technicians and engineers to build and sustain the semiconductor industry. The collaboration will offer three fast-track certification programs to help students develop the skills needed in advanced manufacturing careers. The goal is to provide 25,000 hours of hands-on training and award 500 job-ready workforce certifications over the next three years.

“Across the country we have a deficiency of skilled technicians and engineers who are trained in this field. As we build up the semiconductor industry in the United States, it’s incredibly important that we build up the workforce who will be driving those innovations,” said Hadis Morkoç, Ph.D., a professor in the Department of Electrical and Computer Engineering and the Department of Physics at the College of Humanities and Sciences. “We also need a cultural shift in how we view the potential of the semiconductor industry domestically, and education will play a critical role in keeping this momentum going not just for the next three years but for the next 20 years.”

At the VCU College of Engineering, the VMC is an integral part of the curriculum for electrical engineering students. For example, through the school’s Vertically Integrated Projects and the Capstone program, students can immerse themselves in microelectronics projects by utilizing cutting-edge tools under the guidance of leading experts.

The VMC also provides training opportunities through partnerships with the U.S. military, through which students gain hands-on experiences essential for entering the microelectronics and engineering workforce. This includes the Army Strategic Program for Innovation, Research and Employment (ASPIRE), the Air Force Research Laboratory’s Minority Leaders Research Collaboration Program (ML-RCP) and the Air Force Science, Technology and Research Program (A-STAR), which grants research funding and other resources for students to develop skills in microelectronics and conduct research projects relevant to national needs in technology. The VMC is also working on establishing additional degree and certificate programs specifically for veterans and underserved populations.

“While every clean room facility needs to have the proper tools and equipment, it also more importantly needs highly skilled people to harness these resources,” Dhar said. “The VMC is such a unique and important facility for the microelectronics community, and our vision is to continue to build an ecosystem of research, training and education to drive innovations and technologies for the future.”

Subscribe to VCU News

Subscribe to VCU News at newsletter.vcu.edu and receive a selection of stories, videos, photos, news clips and event listings in your inbox.