Customers fuel 3D Systems’ innovation, new 3D printing technologies at RAPID + TCT 2023 – 3D Printing Industry

US 3D printer manufacturer 3D Systems has showcased its 3D printing technology, materials, software, and application expertise at RAPID + TCT 2023.

3D Systems presented new solutions such as SLS Material Delivery Module, DMP Build Changeover Station, GRCop-42, and CuCr1Zr. The manufacturer believes these solutions will broaden the range of applications for additive manufacturing and “transform” the industries of motorsports, aerospace, semiconductor equipment, and medical device manufacturing.

“Our customers’ innovation fuels ours,” said Marty Johnson, Vice President, Product & Technical Fellow at 3D Systems. “With the collaboration between our application engineers and our customer’s engineering teams, we are collectively pushing the boundaries of what is possible with additive manufacturing. To meet these ever-changing needs, we must constantly evolve our solution portfolio. The addition of the new accessories and materials we are announcing today are the latest examples of customer-centric innovation that are enabling competitive advantage.”

Presenting the new SLS Material Delivery Module and DMP Build Changeover Station

The SLS Material Delivery Module is a newly developed accessory that allows customers to use multiple materials on a single SLS 380 platform with ease. The SLS 380 is a high-throughput SLS additive manufacturing solution that offers unprecedented levels of throughput, consistency, performance, and yield for cost-effective batch production. With the Material Delivery Module, users can quickly change materials with minimal labor, improving machine efficiency and productivity. Additionally, the module enables the use of a broader range of materials, maximizing the value of the platform and expanding the range of applications. The module is also compatible with ProX SLS 6100 and ProX SLS 500 and is expected to be available for order in the second half of 2023.

The DMP Build Changeover Station from 3D Systems is a module that allows for fast turnover of a removable print module in the DMP Factory 500 after a finished build. With the ability to quickly change materials and prepare for the next job, the Build Changeover Station can serve multiple printers in parallel. It is a cost-effective accessory that makes metal AM accessible to a wider range of customers, with the option to upgrade to the full peripheral chain as production demands increase. The DMP Build Changeover Station is now available for ordering.

3D Systems expands its material portfolio

3D Systems has expanded its portfolio with the addition of two new copper alloys – GRCop-42 and CuCr1Zr. GRCop-42 is ideal for high-temperature, high-thermal transfer applications found in rocket engines that require high strength. This material retains its mechanical properties at high temperatures ranging from 400°C to 600°C, making it suitable for high-performance combustion applications in aerospace and space. The inclusion of these materials broadens the range of applications that customers can address with the DMP platform.

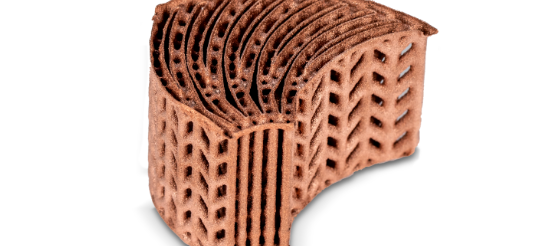

The Certified CuCr1Zr (A) is a copper alloy that boasts high strength, thermal and electrical conductivity, with heat treatment available for enhancing these properties. Customers can collaborate with 3D Systems’ Application Innovation Group (AIG) to tailor heat treatment parameters to meet specific needs. CuCr1Zr is suited for complex heat management systems and electrical applications requiring structural support, such as induction coils and electrical applications. The DMP 350 platform’s (especially DMP Factory 350) low-oxygen environment (<25ppm) makes it suitable for working with copper alloys like CuCr1Zr that are sensitive to oxygen exposure.

3D Systems has made both materials available for immediate ordering.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the CuCr1Zr heat exchanger segment. Image via 3D Systems.