Innovation and value addition pave the way for our success

TAD Group is one of the fastest-growing infrastructure enterprises in the country with a rich and diverse experience spanning three decades.

TAD Group was initiated back in 1995 with sourcing business. Then the company came into the readymade garment (RMG) manufacturing business. Over the years, TAD became the parent of Texweave, TAD Sourcing Ltd. TAD Logistic Ltd., TAD Engineering, TAD Autos, TAD Aviation, TAK international, Maye’s, Replica Creations Ltd. and recently local retail brand Klothen.

With its vivacious portfolio of projects, TAD Group is exclusively placed to build state-of-the-art projects in sectors that are of critical importance in the process of development. Using the Public-Private Partnership model, the Group has successfully leveraged its core strengths to implement several iconic infrastructure projects in Bangladesh.

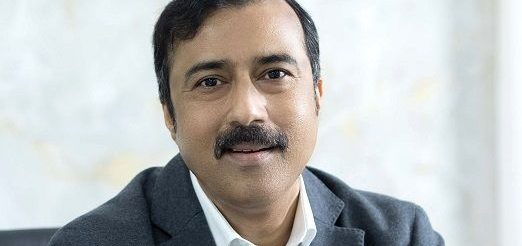

Md. Ashikur Rahman (Tuhin) is a Bangladeshi industrialist and the Founder and Managing Director of TAD Group. He is a Former Director of BGMEA and a current Director of RMG & Textile Industry Skills Council (RTISC).

In a recent interview with Textile Today, Md. Ashikur Rahman shed light on TAD Group and how the Bangladesh T&A industry can faster the growth.

Textile Today: Just like the previous setbacks – Bangladesh textile and apparel (T&A) industry again took off steeply. What are the factors behind this magical recovery?

Md. Ashikur Rahman: Since the beginning of this readymade garment (RMG) industry in 1982 – till this day – the T&A industry has outpaced many mountain scale hurdles – child labor, compliance, the Rana Plaza incident – and COVID was the latest.

I will emphasize that Bangladeshi T&A industry entrepreneurs are vastly experienced in dealing with crises. For instance, in the post- Rana Plaza incident, it was a global conviction that our T&A industry will extinct. Whereas, apparel entrepreneurs have bounced back more robustly. We have not learned to give up.

I will say this happens due to our RMG entrepreneurs’ tremendous willpower and government policy support. Now the T&A industry is the backbone of Bangladesh’s economy. At the same time, Bangladesh is a global icon in green factories, safe working environment, social compliance, etc.

Textile Today: Your factory Macy’s Garments Ltd produces fashionable denim trousers, jackets, cargo pants, etc. What are the new innovative products you offering from your denim ranges?

Md. Ashikur Rahman: In the last 5 to 6 years, Bangladeshi RMG manufacturers have focused on research and development (R&D) in fabric design and development. Once it was our biggest shortfall as we just followed the design made by buyers. Now, R&D is one of our main success catalysts – as we develop our own design and present it to buyers. For the last two years, Macy’s Garments Ltd has heavily focused on sustainable denim products R&D and innovation.

Fashion consumers should know that R&D and innovation are happening continuously in our denim factories. The top priority goes to denim fabric, as denim consumers want diversified denim products. At the same time, we are also focusing on innovative products like denim shacket, reversible wear denim items, and stretch denim – which typically contains elastane, lycra, and acrylic materials, knit denim, etc.

Textile Today: Do you have any investment plan to expand your denim products manufacturing facility considering the global demand boost of denim fashion as well as Bangladesh’s strong position in the global market as a denim supplier?

Md. Ashikur Rahman: In Bangladesh, our capacity for denim production is really top-notch. But we have a shortfall in the backward linkage industry to meet the demand for denim fabrics. As I said above, I like R&D and innovation in denim fabric – TAD Group is planning for a new denim mill with the name TAD Denim. If everything goes accordingly then we will come into production by 2025-26.

In TAD Denim, we will manufacture value-added denim fabric to produce high-end denim products which are most sought after by denim lovers.

Textile Today: Amid the LDC graduation buzzword what is the strategy your company setting to tackle future challenges?

Md. Ashikur Rahman: LDC graduation is completely in the govt. hand as it requires complete policy over overhauling. And yes, only then we can reap benefit from LDC. From Bangladesh textile and apparel industry perspective – by implementing the Accord, Alliance safety standards, USGBC LEED green building certifications and other international standards – we are already ahead in this regard. Now it is government’s role to facilitate all the ports, highways, connectivity and infrastructure related issues to ease of doing business in Bangladesh.

Textile Today: To build skilled labor forces how is your company contributing? And what steps should be taken by the government and BGMEA to build world class employees and workers?

Md. Ashikur Rahman: Building skilled labor forces to increase production efficiency is paramount for our T&A industry. And I myself is a Director of RTISC – which is under the direct supervision of the Prime Minister’s Office. RTISC’s job is to collaborate between all the industry entrepreneurs and related associations like BGMEA, BKMEA, BTMA, BTTLMEA, BGWTF, BGAPMEA, etc. and work to increase worker efficiency.

From the beginning T&A industry has been working relentlessly to increase worker skills and efficiency. As a result, the 3 to 4 million workers are trained and working in the industry. for last 10 years, the T&A factories have industrial engineering (IE) departments, they are implementing Lean Six Sigma practices to enhance efficiency.

The pace will pick up more and more, and we will see the reflection of that.

Textile Today: Which one is more profitable for entrepreneurs—to invest in technology or green infrastructure?

Md. Ashikur Rahman: Our green factory investment has a cost and it increases the apparel prices by 40%.

Bangladeshi T&A industry entrepreneurs have given utmost drive in making their factories green and safe working environment with fair wages. Now the fashion brands should value our investments and give us a fair price.

Entrepreneurs are now investing in technology which really a positive sign. To come out from basic product manufacturing to value-added product manufacturing we need to invest in technology more and more.